ENGINEERING

OUR PROCESS

ADDITIONAL PISTON FEATURES

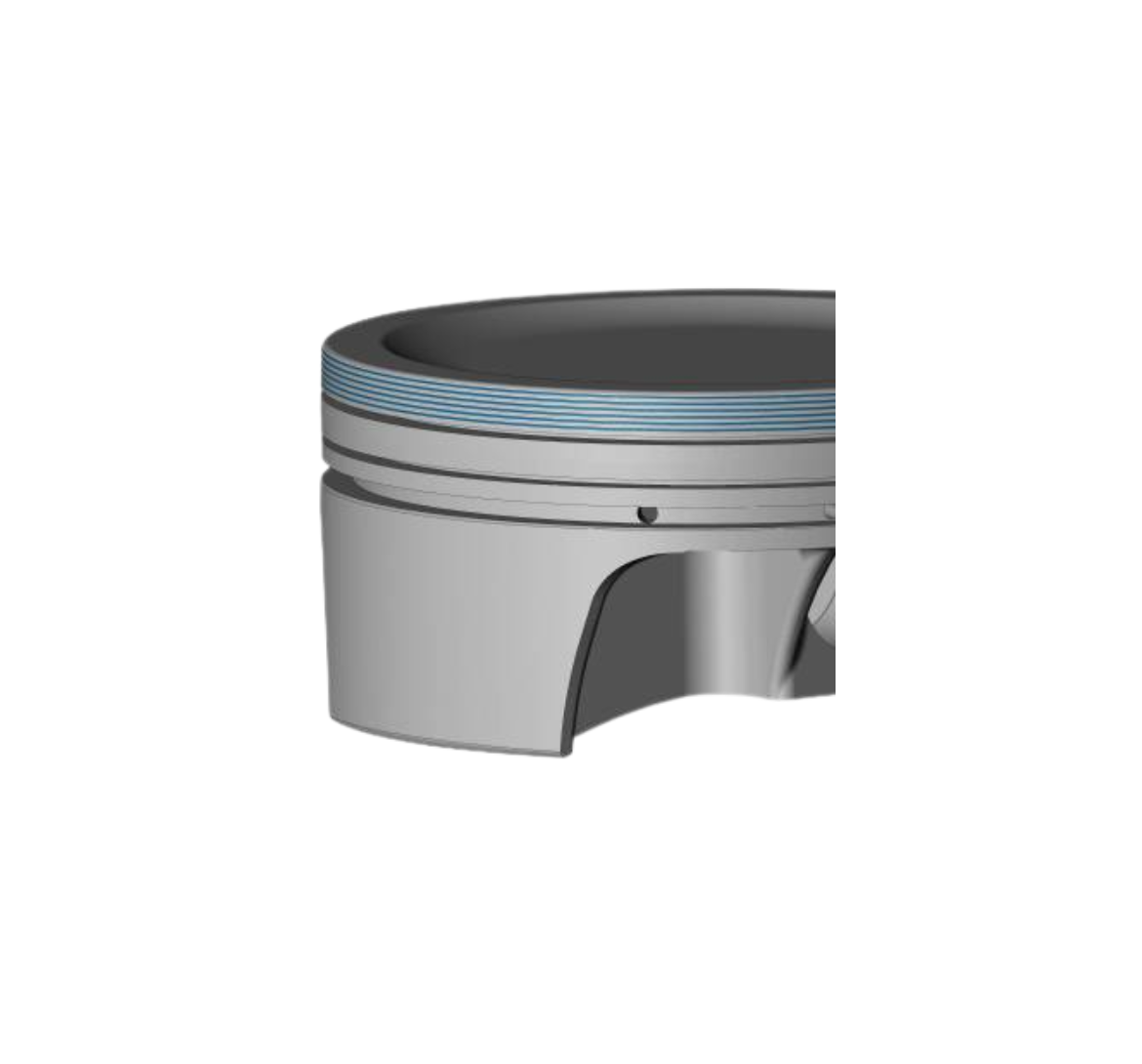

Accumulator Groove

V-shaped groove machined in the 2nd ring land that adds to the volume between the top and second ring. This groove accumulates residual gasses from combustion which alleviates top ring flutter and premature second ring wear, improving ring seal.

Anti Detonation Grooves

Also know as contact reduction grooves, which limit the piston/cylinder contact during high temperature and high RPM. These grooves also protect the top ring by disrupting detonation waves.

Double Pin Oilers

Double Pin Oilers (opposed to single pin oilers), in conjunction with our annular reservoir, can add twice the amount of oil from the cylinder wall to the wristpin bore. This is a standard option on any piston that receives forced pin oiling.

Radius Valve Reliefs

A Radius valve relief is created by using a form tool (or done in a 3D fashion) to roll the edge of the valve relief. Often times we generate radii from valve relief to valve relief as well and this is used to improve flame travel and cross flow in the combustion chamber during the overlap stroke.

Lateral Gas Ports

Lateral gas ports are horizontal slots in the top of the top ring groove and they provide a passage for combustion pressure to get behind and above the top ring, increasing ring seal with reduced radial rings. Lateral gasports are often used over the vertical option when carbon build up (which could clog vertical gasports) may be an issue.

Piston and Connecting Rod Optimisation

Our engineers are able to use our Computer Aided Design (CAD) software in order to optimise the designs for a given application. Using the tools within CAD, we are able to optimally design components for any application. Additionally, these tools also enable us to validate the functionality of our designs.